Product Series

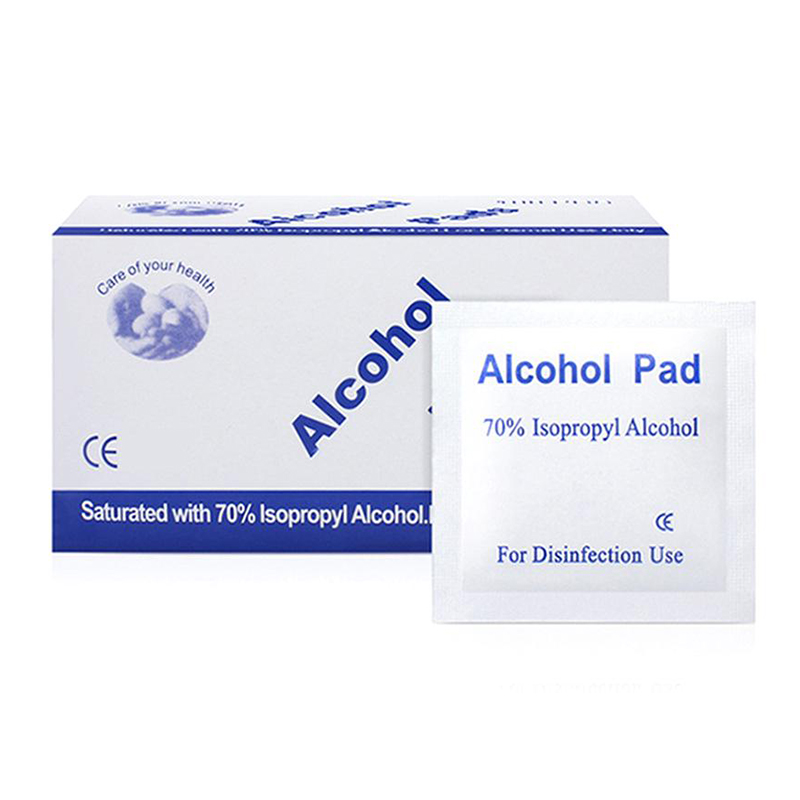

Custom Sterile Alcohol Prep Pads

-

First-Aid Essentials- Alcohol Prep Pads, 100-Pack

Cheap Price Sterile Alcohol Prep Pads 100 Pack Kills 99.9% of Germs

Each box has 100 70% isopropyl alcohol prep pads. Alcohol pads are made with 2pl...

Each box has 100 70% isopropyl alcohol prep pads. Alcohol pads are made with 2pl... -

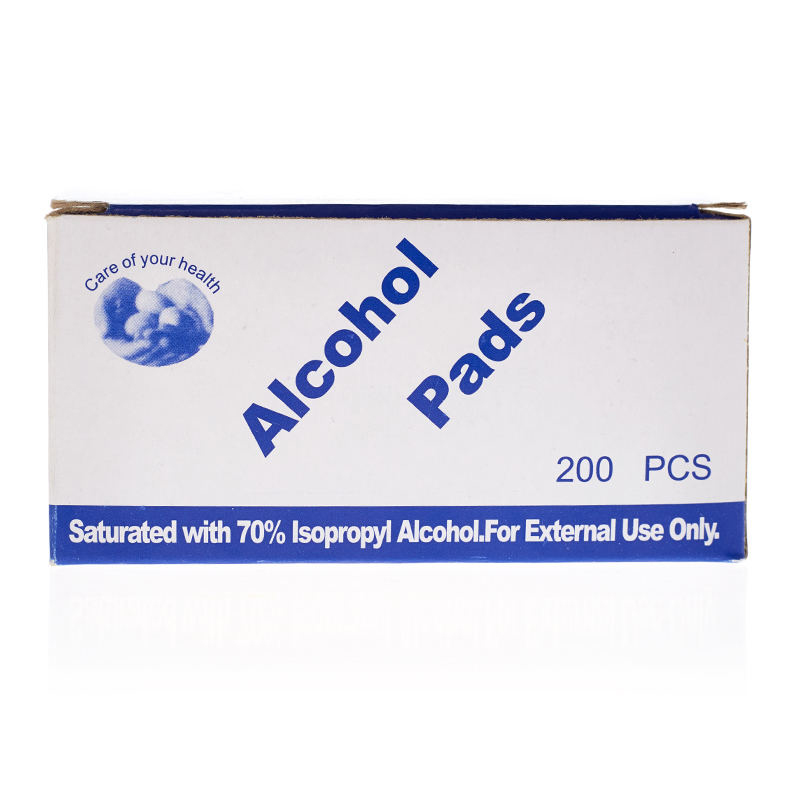

Medical & Professional Alcohol Prep Pad, Sterile, 200-Pack

Disposable Medical 70% Isopropyl Alcohol Prep Pads Non-woven 200PCS

Disposable Medical 70% Isopropyl Alcohol Prep Pads Non-woven 200PCS

Disposable Medical 70% Isopropyl Alcohol Prep Pads Non-woven 200PCS -

Custom Logo ISO/CE Certificated Alcohol Wipes Prep Pads Large Size

Each wipe measures 3.93” x 5.9” and is saturated with 70% isopropyl alcohol. Box...

Each wipe measures 3.93” x 5.9” and is saturated with 70% isopropyl alcohol. Box... -

2-Ply Antiseptic Medium Sterile Alcohol Prep Pad for Fist Aid Kits & Personal Use

75% Medical Sterile Alcohol Wipes Wipes for Hotel and Restaurant

Each wipe size is 1.18”x 2.36” and includes the active ingredient 70% isopropyl ...

Each wipe size is 1.18”x 2.36” and includes the active ingredient 70% isopropyl ... -

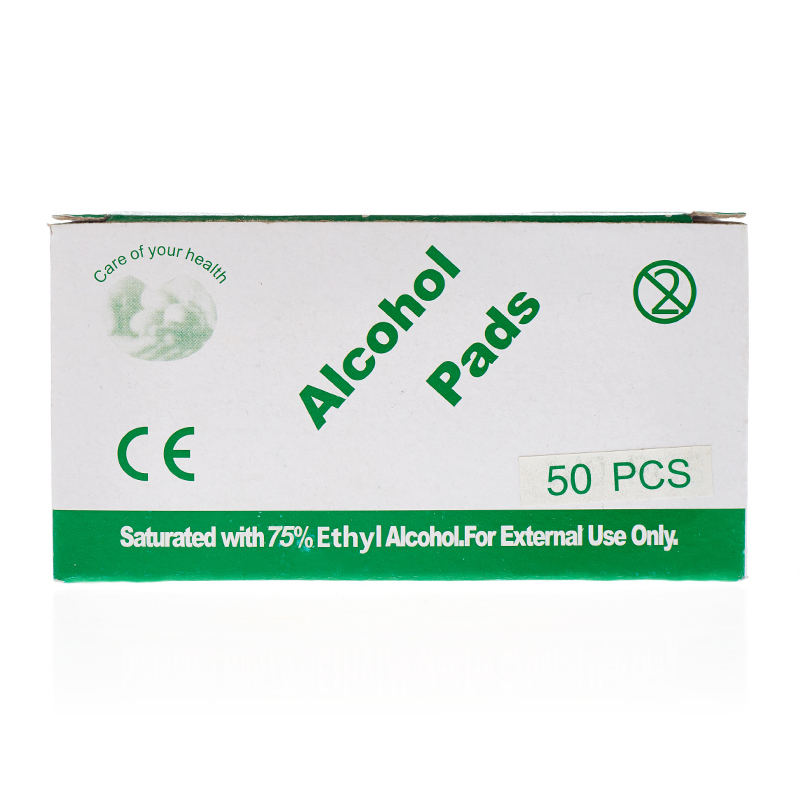

Adults Smirnoff Non-woven Disinfection Alcohol Prep Pads for Household

Instant Mobile Phones Antiseptic Alcohol Prep Pads for Nail Cleaning

Each pad measures 1.18” x 2.36” and is saturated with 75% of ethyl alcohol. Each...

Each pad measures 1.18” x 2.36” and is saturated with 75% of ethyl alcohol. Each... -

Medical Anti-Bacterial Wipes 70% Isopropyl Alcohol Pad Disposable Swab

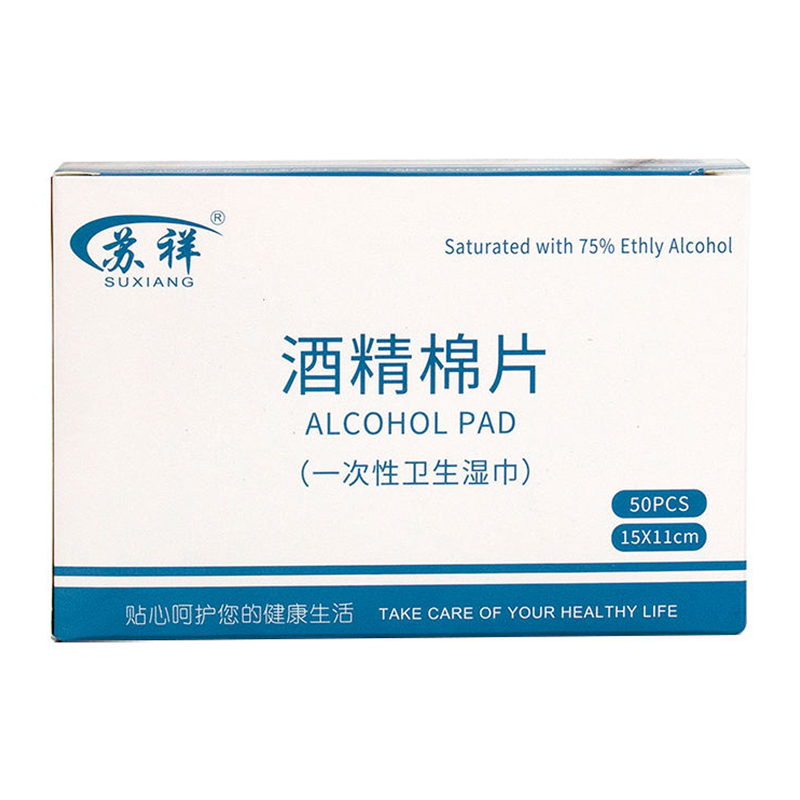

Suxiang Good Quality Ethyl Alcohol Wipes Disposable Hand Sanitizing Wipes

Each pad measures 3.93”x 5.9” and is saturated with 75% of ethyl alcohol. They a...

Each pad measures 3.93”x 5.9” and is saturated with 75% of ethyl alcohol. They a...

Alcohol pads, also known as alcohol swabs or prep pads, are indispensable tools in maintaining hygiene and preventing infection in various settings. The 70% isopropyl alcohol content effectively kills bacteria, viruses, and other microbes on contact, promoting a sterile environment to minimize the risk of infections.

The individually wrapped pads ensure sterility and portability, making them ideal for on-the-go use. These convenient and portable wipes are saturated with isopropyl alcohol, a powerful antiseptic, making them an essential part of first aid kits, medical facilities, and everyday personal care routines.

Beyond medical applications, alcohol pads serve a variety of purposes, such as sanitizing surfaces, cleaning electronic devices, and disinfecting everyday items. Their versatility and ease of use make them a valuable resource for maintaining cleanliness in diverse environments.

Whether you're a healthcare professional, a traveler, or simply someone who prioritizes cleanliness, alcohol pads are a reliable choice for convenient, on-the-spot disinfection. Keep these pads within reach to ensure a quick and effective solution for maintaining hygiene wherever and whenever it's needed.

About us

We are a disposable wipes manufacturer.

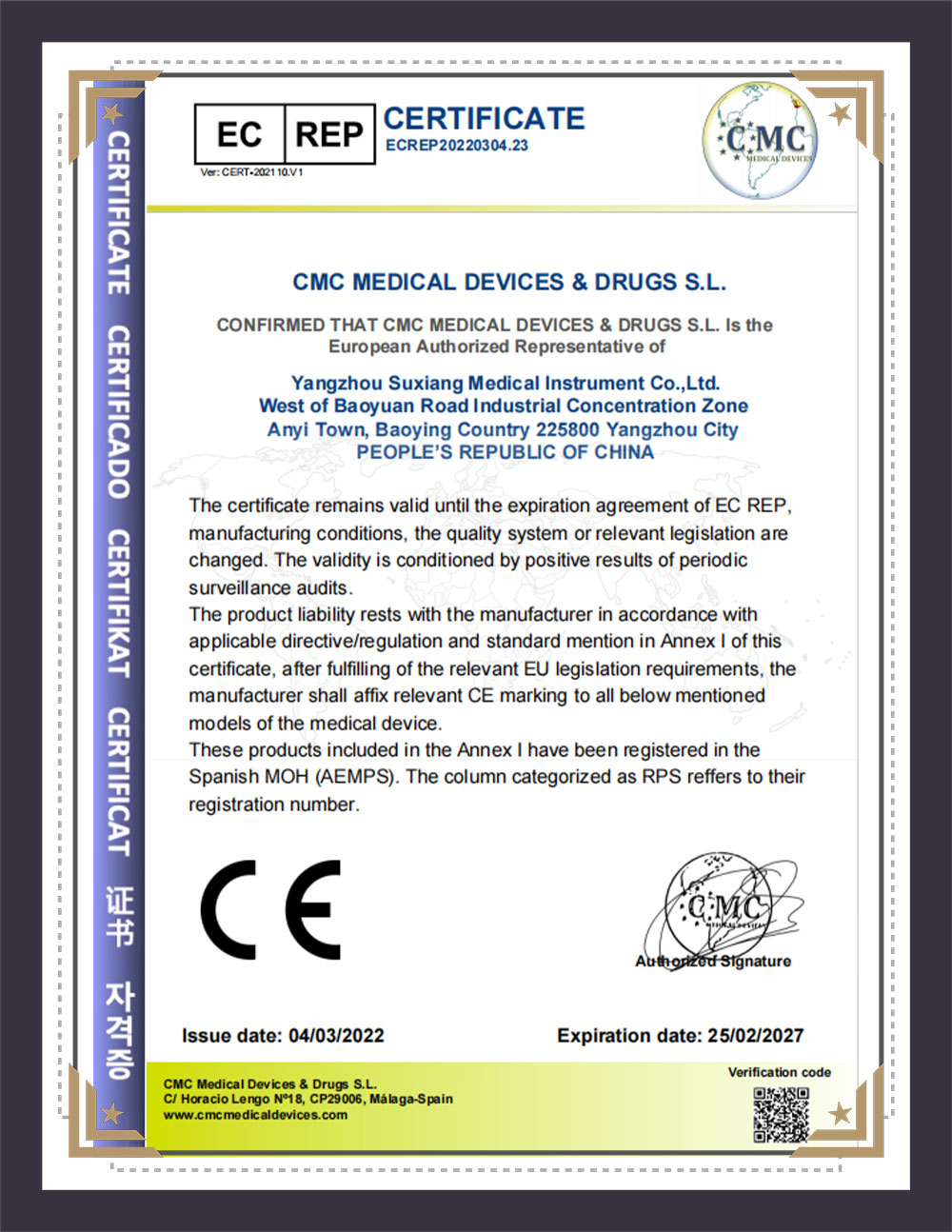

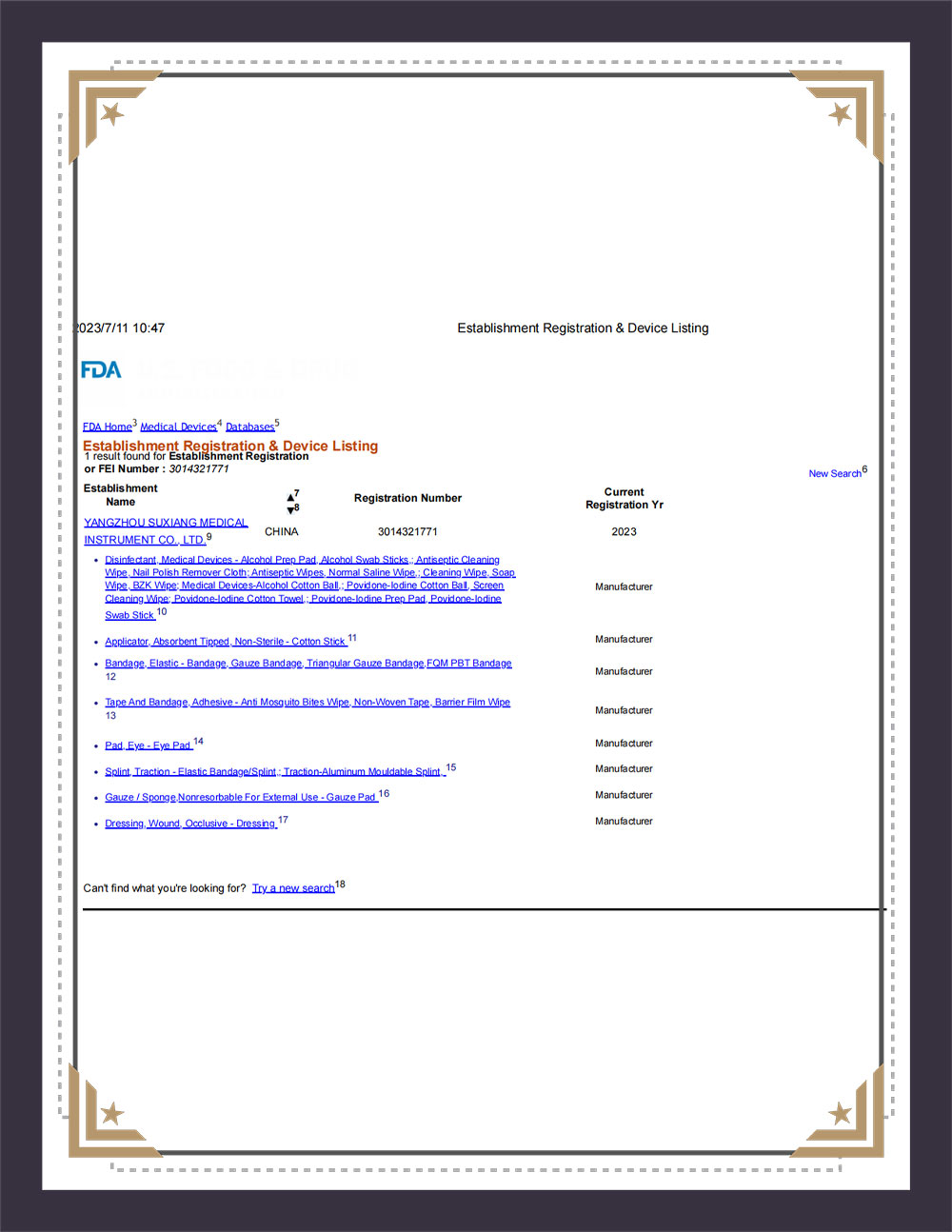

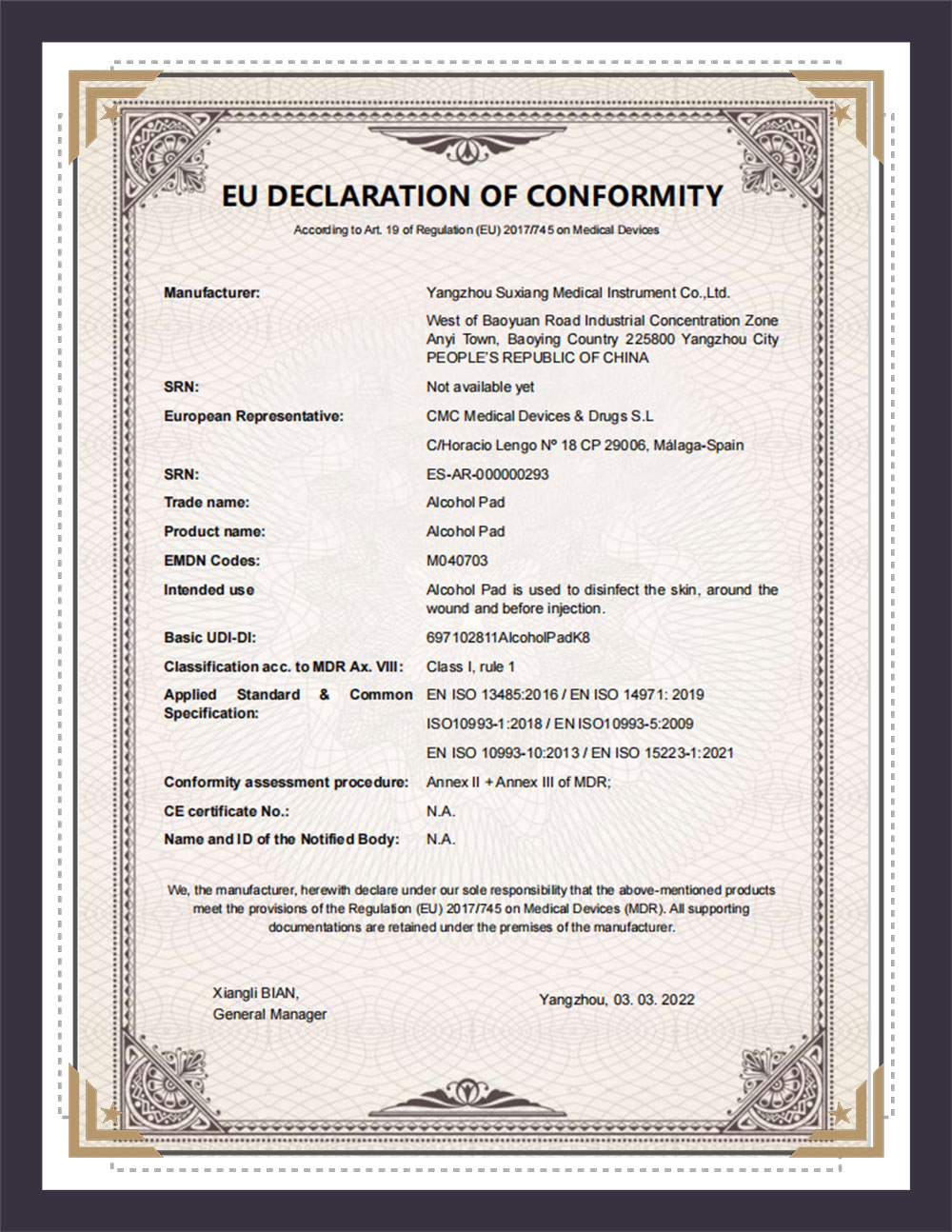

Yangzhou Suxiang Medical Instrument Co., Ltd., specializing in the production, processing and sales of disposable wipes, the main products are medical alcohol pads, medical povidone iodine pads, screen cleaning wipes, disinfectant wipes, baby wipes, multifunctional wipes, first aid kit accessories, advertising wipes. We are China OEM 70% Isopropyl Alcohol Swabs Suppliers and Custom Sterile Alcohol Prep Pads Manufacturers. Our company plant area is 4000 square meters, has 60+ employees. In recent years, the company has introduced a series of advanced equipment, with single wet wipes, multiple wet wipes packaging machine more than 100 sets, the daily output can reach 10 million bags. We also support OEM, ODM, to provide customers with personalized customized services. In addition, our company has obtained ISO13485, ISO9001, BSCI certification, products have CE, FDA, NDC, MSDS, SGS, chemical safety transportation and other foreign certificates. We focus on developing high-quality products for top-end markets. And our products sell well throughout the country, exported to the United States, Europe, Japan, Southeast Asia and other countries and regions.

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

NEWS

During the production process, how do sterile alcohol prep pad manufacturers perform multiple sterilization processes when making sterile alcohol prep pads?

During the production process, sterile alcohol preparation pad manufacturers will adopt a series of strict disinfection measures to ensure the sterility of the product.In the selection of raw materials, manufacturers will strictly screen and process them to ensure that the raw materials themselves have no risk of microbial contamination. These raw materials are usually non-woven fabrics or other suitable materials that undergo pre-treatment steps such as cleaning, drying and disinfection to remove bacteria and impurities on the surface.

During the alcohol addition process, manufacturers use pure alcohol and perform precise metering and mixing through professional equipment and processes. Alcohol acts as an effective bactericide and can kill most bacteria and viruses. The manufacturer ensures that the alcohol content on each prep pad meets standards for optimal disinfection.

After the addition of alcohol is complete, the prep pad enters the disinfection process. Manufacturers will fully disinfect prep pads using methods such as high-temperature steam, ultraviolet radiation, or chemical disinfectants. These disinfection methods can effectively kill remaining microorganisms and ensure the sterility of the preparation pad.

Manufacturers will also set up multiple testing points on the production line to perform microbiological testing on prep pads. Through sampling and laboratory analysis, manufacturers can promptly identify and address any potential microbial contamination issues.

During the packaging stage, manufacturers use sterile packaging materials and ensure the hygiene and sterility of the packaging process. Once packaged, the prep pads are microbiologically tested again to ensure they remain sterile before leaving the factory.

Sterile alcohol prep pad manufacturers ensure the sterility of their products during the production process by selecting high-quality raw materials, precise addition of alcohol, comprehensive disinfection processing, and sterile packaging. These measures jointly ensure that the sterile alcohol preparation pad can maintain a high degree of sterility before use, thereby effectively killing bacteria and viruses and protecting the health and safety of users.

70% isopropyl alcohol swab suppliers choose sealed packaging. What role do 70% isopropyl alcohol swabs play in the production process?

The choice of sealed packaging for 70% isopropyl alcohol swabs during the production process plays a key role in ensuring product sterility, maintaining alcohol concentration and improving product safety.Sealed packaging plays a central role in maintaining sterility. During the production process of cotton swabs, although the sterility of the cotton swabs has been ensured through multiple sterilization processes, without proper packaging for protection, the cotton swabs are easily contaminated by external microorganisms during subsequent transportation and storage. Sealed packaging can effectively isolate the external environment and prevent the intrusion of microorganisms, thereby ensuring that the swabs remain sterile throughout the entire supply chain.

Sealed packaging helps maintain the concentration of alcohol on the swab. Isopropyl alcohol is the main disinfectant component of cotton swabs, and the stability of its concentration is crucial to the disinfection effect of the product. Sealed packaging can prevent the evaporation of alcohol and ensure that the swab can still maintain sufficient alcohol concentration after long-term storage, thereby maintaining its efficient disinfection ability.

Sealed packaging also increases product safety. Because isopropyl alcohol is flammable, it can pose a safety hazard if not properly packaged and stored. Sealed packaging can not only effectively prevent the leakage of alcohol, but also reduce contact with air and reduce the risk of fire.

Sealed packaging plays a vital role in the production process of 70% Isopropyl Alcohol Swabs. It can not only maintain the sterility of cotton swabs and maintain the stability of alcohol concentration, but also improve product safety. Therefore, for suppliers, choosing high-quality sealed packaging materials and strictly implementing packaging processes is an important part of ensuring product quality and safety.