News categories

Product categories

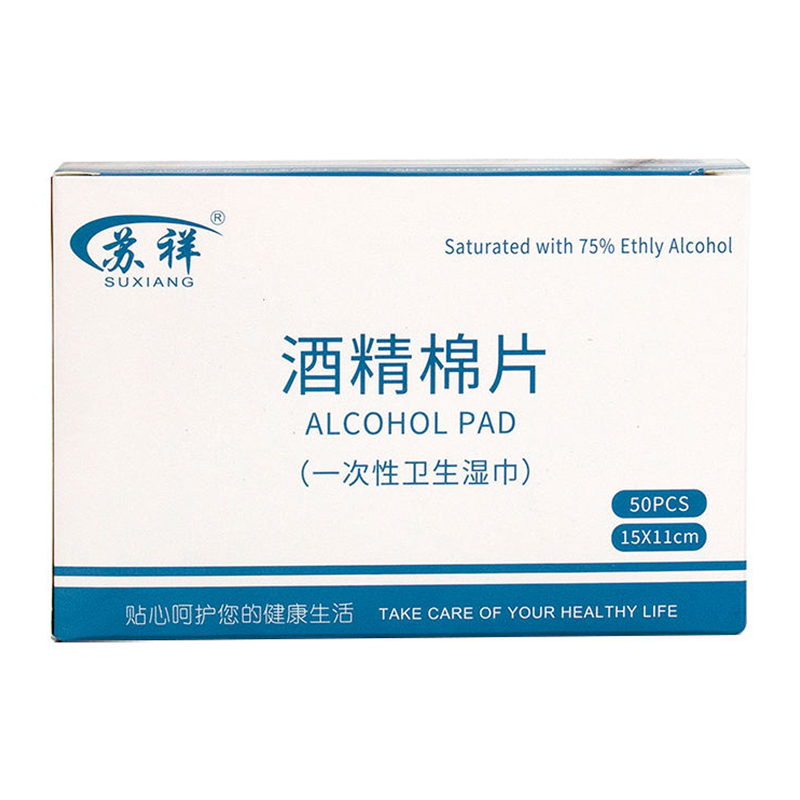

Disinfecting Wipes: Guardians of Hygiene in Modern Life

In today's fast-paced lifestyle, personal and public health safety is increasingly important. Disinfecting wipes, as a convenient and efficient cleaning and disinfection tool, are gradually becoming indispensable daily necessities in homes, offices, medical institutions, and public places.

Material Composition and Technical Characteristics of Disinfecting Wipes

The core of disinfecting wipes lies in the organic combination of their material structure and disinfectant formula. The wipe base material is typically made of high-strength, non-woven fabric, formed into a multi-layered structure through ultrasonic or hot-pressing technology, giving it both excellent absorbency and preventing breakage or lint during use. The non-woven fabric surface undergoes special treatment to effectively maintain the even distribution of disinfectant, improving disinfection efficiency.

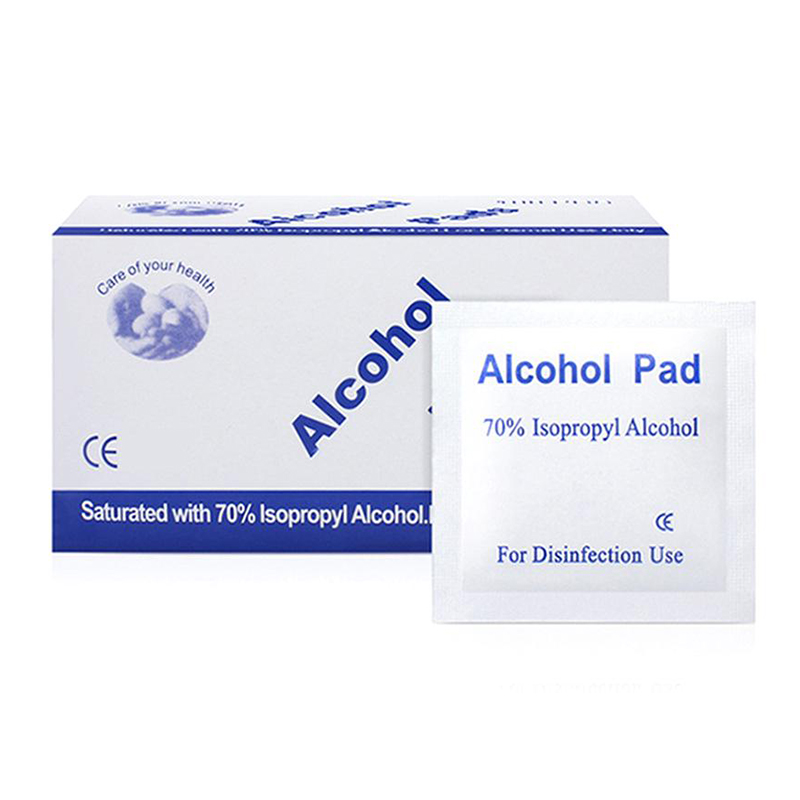

Common ingredients in the disinfectant include active disinfecting agents such as alcohol, quaternary ammonium salts, and hydrogen peroxide. These ingredients can quickly destroy the cell membranes or protein structures of bacteria and viruses, achieving rapid sterilization. High-quality disinfecting wipes are also designed with skin and surface material safety in mind, ensuring that they do not cause corrosion or allergic reactions during widespread use.

Functional Characteristics of Disinfecting Wipes

The core value of Disinfecting Wipes lies in their "convenience, efficiency, and safety." Convenience is one of their biggest advantages. Users don't need to prepare additional disinfectant or tools; simply open the package to clean, making them particularly suitable for mobile scenarios or public transportation. Efficiency is reflected in their broad-spectrum bactericidal ability, instantly inhibiting or inactivating various bacteria, viruses, and fungi. Safety is also a key focus of industry research; high-quality products achieve a balance between disinfection efficacy and human safety, making them suitable for various scenarios such as hands, desktops, and electronic device surfaces.

Disinfecting wipes also exhibit anti-drying and long-lasting properties. Through optimized packaging sealing design and liquid formula, the wipes remain moist and the active ingredients remain stable for a long time after opening, ensuring the disinfection effect of each wipe during use.

Applications of Disinfecting Wipes in Daily Life and Professional Scenarios

Disinfecting wipes have an extremely wide range of applications. In the home environment, they are used to clean kitchen countertops, door handles, household appliances, and children's toys, providing daily protection for family members. In the office environment, disinfecting desktops, keyboards, telephones, and office equipment is an important means of maintaining a healthy working environment. In medical institutions and laboratories, disinfectant wipes play a crucial role in infection control, rapidly cleaning and sterilizing frequently touched surfaces to reduce the risk of cross-infection.

Beyond these conventional applications, the demand for disinfectant wipes is also growing in public transportation and commercial spaces. Airports, subways, hotels, and the catering industry all use them as a key tool to improve public health standards, enabling the rapid and effective control of the spread of pathogens in high-traffic environments.

Market Trends and Innovative Development of Disinfectant Wipes

With increasing consumer awareness of health and hygiene, the disinfectant wipes market is showing a steady growth trend. Product development is moving towards higher efficiency, environmental friendliness, and portability. On the one hand, low-irritant wipes with alcohol-free or natural ingredients are popular, especially among infants and sensitive individuals. On the other hand, biodegradable or environmentally friendly packaging designs are becoming a highlight of industry innovation, balancing functionality with sustainable development needs.

Technological innovation is also driving the development of disinfectant wipes towards multi-functionality. For example, some wipes, by adding antiviral factors or fragrance ingredients, not only provide sterilization but also offer a comfortable user experience. Improvements in smart packaging and dispensing technologies enable wipes to maintain optimal humidity and active ingredient stability in various scenarios, thereby extending product lifespan and enhancing ease of use.

Quality Standards for Disinfecting Wipes: The industry maintains extremely strict quality control for disinfecting wipes. Products must meet relevant disinfection standards and regulations, including active ingredient concentration, bactericidal spectrum testing, and skin safety assessments. Companies must implement rigorous raw material selection, production process control, and finished product testing during production to ensure that each batch meets standards. Simultaneously, packaging labels must clearly indicate ingredients, uses, usage methods, and precautions, providing consumers with clear guidance.

As an indispensable hygiene tool in modern life, the value of disinfecting wipes lies not only in their convenience and disinfection efficiency but also in enhancing public health awareness and quality of life. In the future, with continuous advancements in materials technology, disinfection formulations, and intelligent design, disinfecting wipes will evolve towards greater efficiency, safety, environmental friendliness, and multifunctionality, becoming an important assistant for maintaining health in homes, offices, medical institutions, and public places.

related products

Copyright © Yangzhou Suxiang Medical Instrument Co., LTD. The information provided on this website is intended for use only in countries and jurisdictions outside of the People's Republic of China. Wholesale Disposable Cleaning Wipes Suppliers