News categories

Product categories

Alcohol Wipes: An Effective Choice for Modern Disinfection and Cleaning

With health and hygiene increasingly valued, alcohol wipes have become an indispensable cleaning product in both daily life and healthcare. Portable, fast, and effective, they are widely used in a variety of settings, including personal protective equipment, medical institutions, public spaces, and industrial production. With growing awareness of disinfection safety, market demand for alcohol wipes continues to grow, and their technology and materials are constantly evolving, gradually transforming them from traditional cleaning products into intelligent, specialized ones.

Core Ingredients and Mechanism of Action of Alcohol Wipes

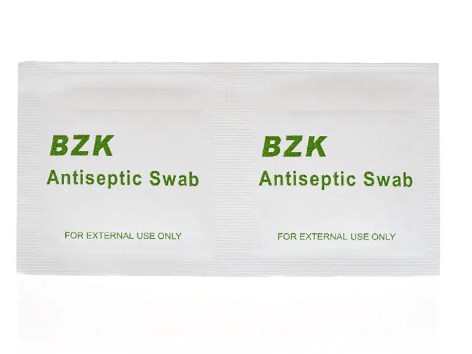

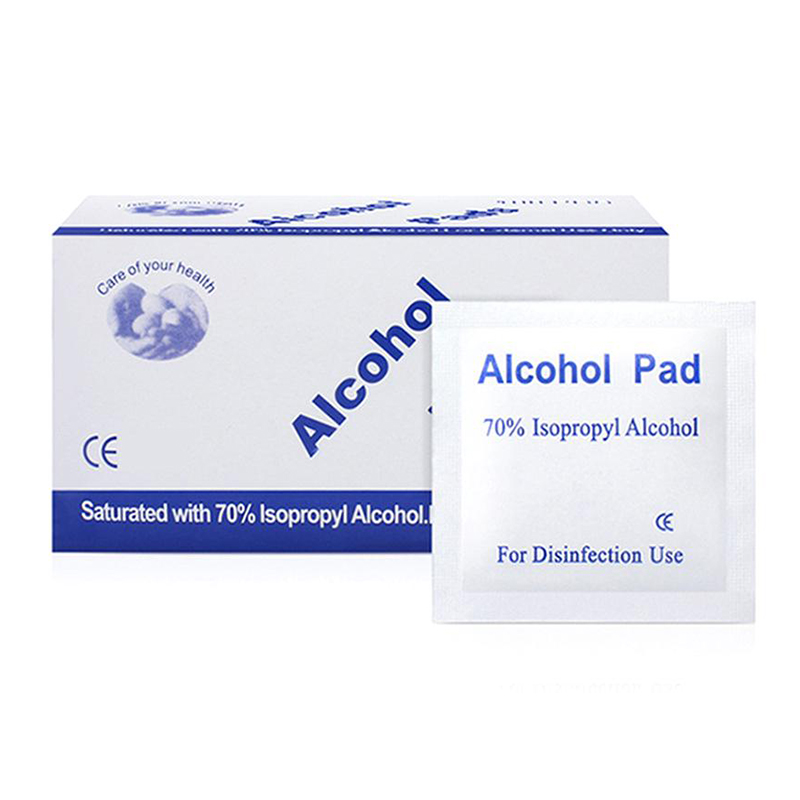

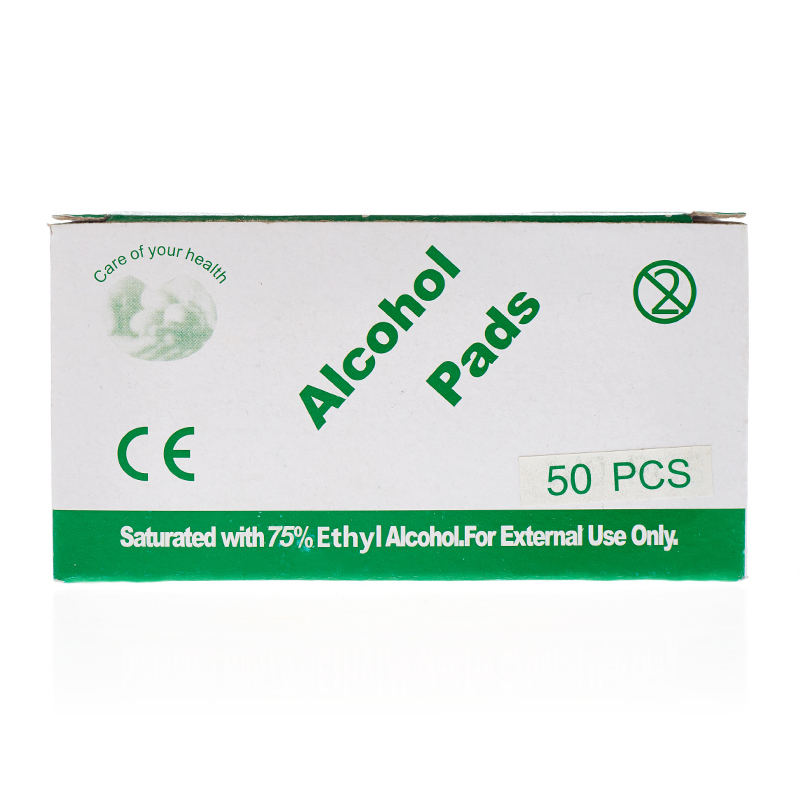

Alcohol wipes are primarily composed of ethanol or isopropyl alcohol, organic solvents with high volatility and bactericidal properties. Their mechanism of action is to disrupt microbial cell membranes and denature proteins, achieving both antibacterial and sterilizing effects. The effectiveness and safety of the wipes depend on the appropriate alcohol concentration, which is typically maintained at a high level to ensure efficient removal of common bacteria and some viruses. Modern formulas also incorporate moisturizers and softening agents to reduce alcohol irritation and enhance comfort and skin-friendliness.

High-quality alcohol wipes require precise control of the liquid content and uniformity of each wipe to avoid uneven wetness. The carrier material has also evolved from standard non-woven fabrics to polymer composite fibers, which offer improved adsorption and tear resistance, resulting in a more balanced alcohol evaporation rate and ensuring a long-lasting and stable disinfection effect.

Wide Applications in Healthcare and Daily Protection

In healthcare, alcohol wipes are a crucial component of standardized disinfection procedures. They are used for hand hygiene by medical personnel, wiping medical equipment surfaces, and disinfecting injection sites. Their rapid sterilization properties not only effectively prevent cross-infection but also significantly improve work efficiency.

In personal protection, alcohol wipes, with their portability and disposable nature, have become a hygiene companion for travel, work, dining, and other occasions. Driven by public health emergencies, more and more consumers are making alcohol wipes a staple in their daily routines. Brand manufacturers are continuously optimizing packaging design and evaporation control technologies to better meet the consumption habits and health needs of modern users.

Material and process innovations drive product upgrades.

With advances in materials technology, the production of alcohol wipes has evolved from traditional processes to a more efficient and intelligent stage. High-quality nonwoven fabric substrates must not only exhibit high absorbency and breathability, but also maintain softness and structural stability. Some manufacturers utilize spunbond and hydroentangled composite technologies to achieve a more delicate feel while maintaining strength, making them suitable for use on the face and sensitive skin areas.

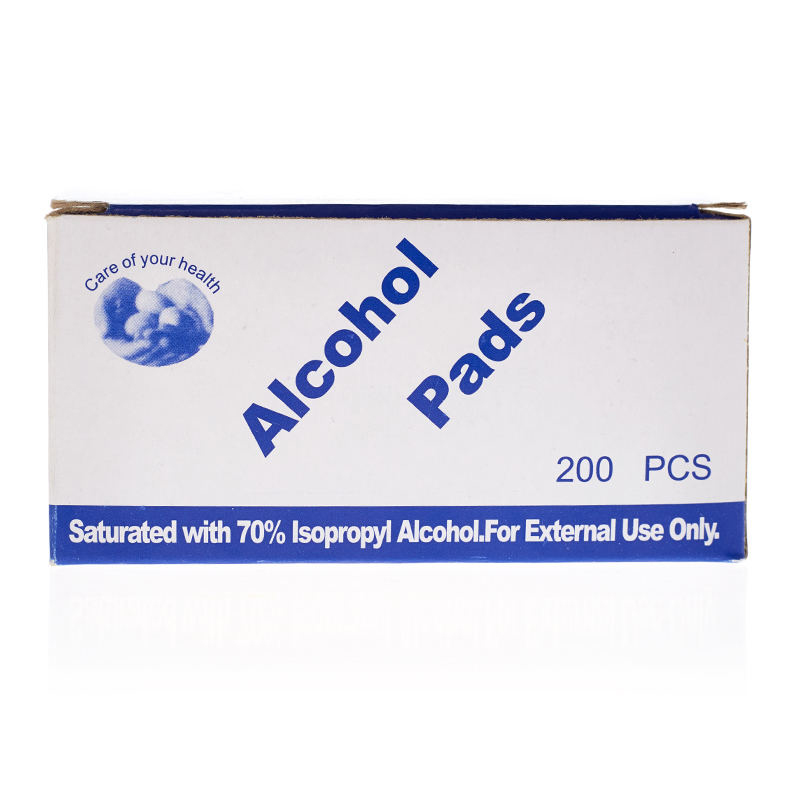

The degree of automation in production equipment is also a key factor in determining quality consistency. Modern production lines enable automated monitoring throughout the entire process of raw material feeding, impregnation, cutting, and packaging, effectively preventing human contamination and ensuring consistent product hygiene standards. Furthermore, improved packaging sealing significantly extends the shelf life of the wipes, ensuring they retain sufficient moisture and disinfecting effectiveness even after extended storage.

The Importance of Safety and Standardized Production

Despite their widespread use, alcohol wipes remain a key industry regulatory concern. Manufacturers must strictly adhere to relevant hygiene standards and chemical safety regulations to ensure the stability of alcohol content, pH value, and additives. High-quality products should avoid harsh preservatives and artificial fragrances to ensure they don't cause skin irritation with frequent use.

A standardized production management system effectively ensures product consistency and reliability. By establishing rigorous raw material testing, production monitoring, and factory inspection mechanisms, manufacturers can not only enhance their brand credibility but also provide consumers with safer, more professional hygiene solutions. With the convergence of international standards, the alcohol wipe industry will further develop towards standardization and branding.

Alcohol wipes are not only a convenient cleaning and disinfecting tool, but also represent the modern consumer's emphasis on health and quality of life. With technological advancements and evolving consumer awareness, their application scenarios will continue to expand, and product forms will become increasingly diverse. From basic disinfection functions to comprehensive care experiences, alcohol wipes are leading the future of the hygiene protection industry with innovation and quality.

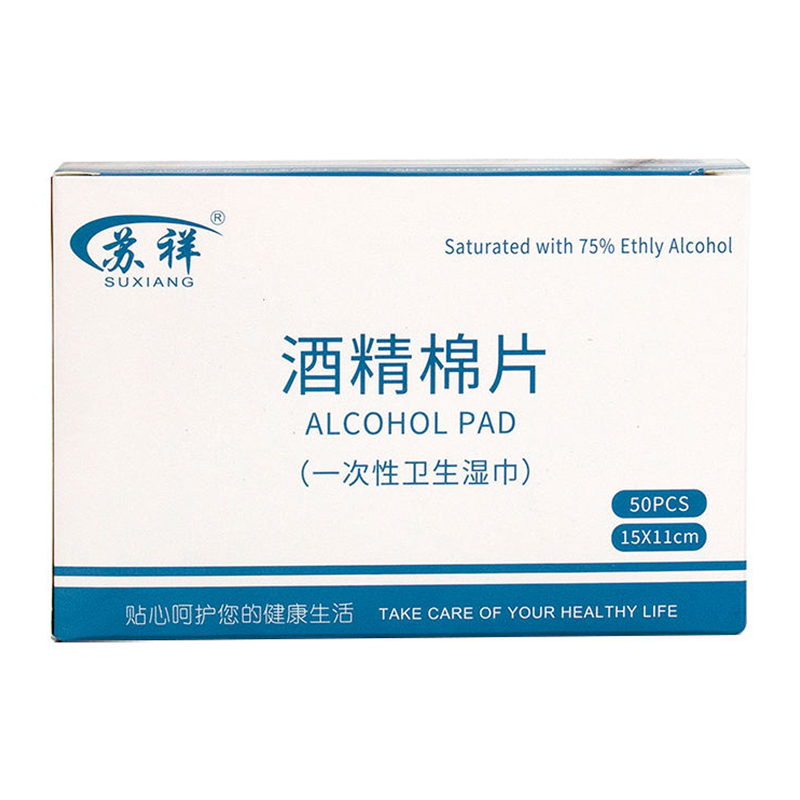

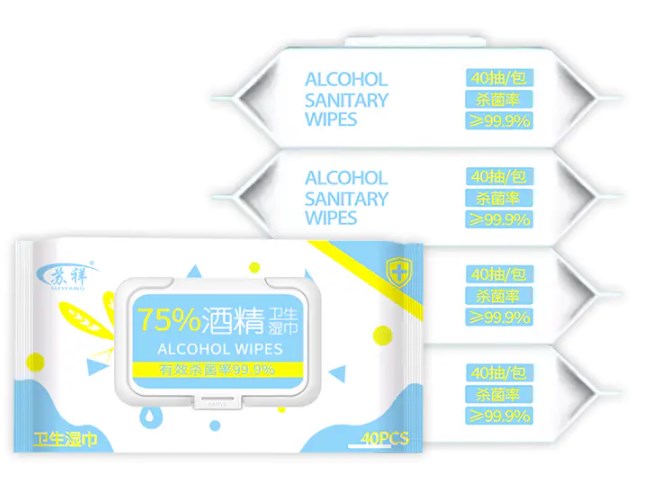

related products

Copyright © Yangzhou Suxiang Medical Instrument Co., LTD. The information provided on this website is intended for use only in countries and jurisdictions outside of the People's Republic of China. Wholesale Disposable Cleaning Wipes Suppliers